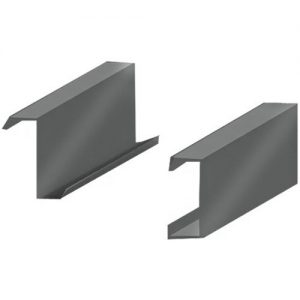

We are leading Manufacturers of C AND Z (ZED) PURLINS. We have a wide range of distributor &  dealer base of C and Z Purlin in Chennai, Tamilnadu & other Southern states of India. Our category of Purlin “C” & “Z” is notable because it can be customized as per our customer’s specifications. Additionally, professionals have designed our range to ensure that when lapped, a continuous line can be formed down the length of a building, and are extremely cost effective by reducing the structural total weight requirement by almost 20 percent.

dealer base of C and Z Purlin in Chennai, Tamilnadu & other Southern states of India. Our category of Purlin “C” & “Z” is notable because it can be customized as per our customer’s specifications. Additionally, professionals have designed our range to ensure that when lapped, a continuous line can be formed down the length of a building, and are extremely cost effective by reducing the structural total weight requirement by almost 20 percent.

Salient Features:

The hallmark feature of our purlin production facility is the capability to manufacture purlins, to the required dimensions, tailor made to client’s and consultant’s specifications. The new advanced production facility is installed with a view to enable the clients to place orders to their exact needs viz. Optimum sizes with cost benefits.

The Customized size options can be provided in all dimensional area of the purlin(Web, Flange, Lip, Length and holes). Perfect lapping of purlin sections enable continuous line throughout the length of the building and also attributes to cost saving.

With the installation of heavy duty high rated production facility, we can achieve continuous large scale production, and thus would cater to huge and unhindered supplies, with in the committed schedule.

It is the practice in the steel industry that structural shapes are assigned representative designations for convenient shorthand description on drawings and documentation: Channel sections, with or without flange stiffeners, are usually referenced as C shapes; Channel sections without flange stiffeners are also referenced as U shapes; Point symmetric sections that are shaped similar to the letter Z are referenced as Z shapes. Section designations can be regional and even specific to a manufacturer. In steel building construction, secondary members such as purlins (roof) and girts (wall) are frequently cold-formed steel C, Z or U sections, (or mill rolled) C sections.

Cold formed members can be efficient on a weight basis relative to mill rolled sections for secondary member applications. Additionally, Z sections can be nested for transportation bundling and, on the building, lapped at the supports to develop a structurally efficient continuous beam across multiple supports.